Surface Improvements

When 3D printing (originally SLS) was invented in 1984 the concept attracted interest from designers and innovators alike. It was

When 3D printing (originally SLS) was invented in 1984 the concept attracted interest from designers and innovators alike. It was

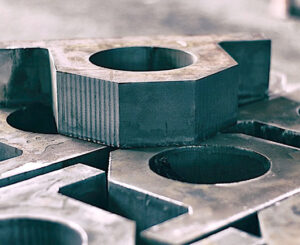

Vibra Finish has logged close to half a century of experience in finishing metal parts for Canadian businesses. Their process involves

Vibra Finish has served Canadian businesses since 1971 with the most diverse range of finishing services and skills. One key

For close to half a century, Vibra Finish has offered industrial metal-finishing services above and beyond customer expectations. The company’s

Vibra Finish has mastered every aspect of the metal-finishing process – including cleaning, polishing, smoothing, and deburring – making it

A common deburring machine used for mass-finishing parts is a vibratory deburring machine, or vibratory tumbler, which utilizes abrasive tumbling

Kumar Balan explores the efficacy of vibratory peening, its financial viability and its potential market reach. His article will cover

When parts require strong surfaces, there are several methods used to achieve the desired hardness and durability, including nitriding, shot

Vibra-Peen Machine Parameters Almen strip readings (force/energy) ~ amplitude of vibration (how hard hit). Saturation effects – amplitude of vibration

Although vibratory finishing techniques are similar to barrel finishing and usually involve the same components (water, compound and media), the