When 3D printing (originally SLS) was invented in 1984 the concept attracted interest from designers and innovators alike. It was futuristic and unique and the notion fertilized considerations of what many uses “printing” could have however, the technology was young and limitations were apparent. It would be two decades and many R&D hours later before it would be available for on-demand manufacturing. This happened in 2006.

Since the first on-demand printers were put to use, most applications were limited to creating prototype models used as references and demonstrations of parts that would be made using traditional manufacturing techniques. The continuous developments have grown concepts and potential uses into the production of usable, functioning parts.

It is now 2019 and the capabilities of part printing are seen in a range of materials and applications found in industries from automotive and aerospace to everyday consumer goods, but one issue still limits further advancement of the 3D printing industry’s almost limitless potential; Stair stepping.

Stepping is a common issue, a result of printing a part from the bottom up, adding material layer by layer. With intricate parts with varying geometries, some layers are wider than others, creating a “stair” like step from one layer to the next. Although this issue is constantly being improved resulting in tighter tolerances, the fine steps on the finished parts surface still exist and can create both aesthetic and functionality issues.

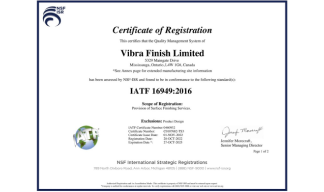

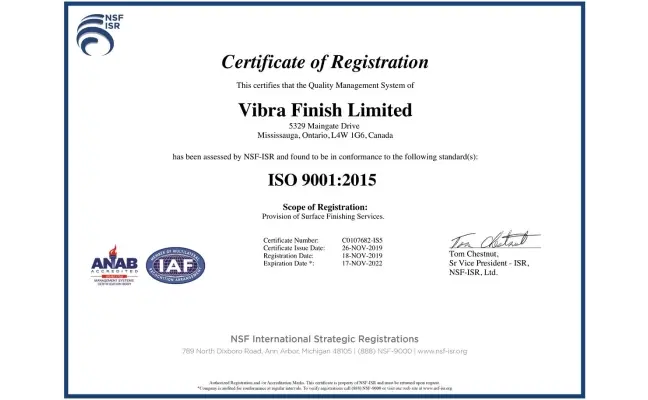

A large portion of our business at Vibra Finish Ltd in Mississauga is surface improvement of parts manufactured using many different methods. We not only process parts in-house, we also manufacture the equipment to do the job and develop processes with special media and compounds that our customers can use in their facilities with our equipment. Recently we have seen a significant number of requests for this requirement, specifically from customers who have purchased 3D printers to make their own parts as well as manufacturers who make the printers themselves. Most of the materials used to make these parts are more resistant to traditional vibratory finishing. This was apparent during our early testing on these parts which we began a few years ago. To directly compare our results we processed two similar parts made from the same materials that are common in printing such as nylon, plastic, stainless steel, aluminum, and nitinol. For the test we used one part that was 3D printed, the other was machined or casted. The printed parts showed a significantly less wear rate than those made using other methods which meant in order to attain the same level of finishing; it required more consumption of water and medias as well as longer processing times. There are media on the market that have higher abrasives which reduce cycle times but the trade-off is the rate of wear in medias which can be significant.

Since these discoveries we have run thousands of parts for customers with varying requirements of printed parts. Our successes have come from our R&D department who have been working alongside our media suppliers developing new media of different shapes and sizes to accommodate different part geometries. These new 3D specific medias also contain a high level of abrasive, similar to “fast-cutting” media with bond compositions that are dense to combat the wear levels that take place when running extended cycle times.

These new products along with our application specific, custom-built machines have opened up the gates where final-finish processing, done often by hand had previously bottle-necked the production volume.

The history of media finishing goes back centuries, long before sophisticated machinery would do the job for us. The concept is basic but the need for the application’s improvements are in high demand. With the manufacturing industry ever changing, it will continue to grow as the technologies of our time force us forward. You print the parts, we will finish things up. It’s what we do.

Zach B. McGillivray

Business Development/R&D Manager

Vibra Finish Ltd

Do you have experience working with complex medical devices?

Do you have experience working with complex medical devices?