About Us

50+ years of experience

Serving Worldwide

Vibratory Finishing, unlike hand polishing, buffing, filing, belting, does not overly depend on the skill of the operator. Instead, it is a mass finishing technique lending itself to batch security and uniformity for the lot. Parts are typically bulk loaded for a long batch process or continuously fed into a vibratory machine for a cellular manufacturing system. Media of various compositions and sizes are used in the bowl. The vibratory action causes the media to act like thousands of small files scrubbing the parts. A chemistry is used to assist the cleaning/finishing action of the media. The amplitude and frequency of the vibration can be varied to control the finishing of the parts. In vibratory finishing equipment, the angle between the upper and lower weight system can be varied to adjust the ratio between the forward feed motion and the rolling action of the media mass. The process is commonly used to deburr, burnish, descale, clean, radius, and improve surface finishes. It is ideal for finishing parts prior to painting, plating, heat treating, anodizing, coating and sometimes it is the ideal final finish.

OUR MISSION

At Vibra Finish Limited, our mission is to deliver exceptional surface finishing solutions that enhance the quality, durability, and aesthetics of our clients’ products. We strive to achieve excellence through advanced techniques, eco-friendly practices, and unmatched customer service, forging lasting partnerships with industry leaders and exceeding expectations in every project we undertake.

OUR VISION

Our vision is to be a globally recognized metal finishing company, renowned for our cutting-edge technologies, unmatched quality, and customer-centric approach. We aspire to revolutionize the metal finishing industry by providing innovative solutions that not only meet but exceed the diverse needs of our clients, building enduring partnerships and leaving a lasting mark of excellence in every finish.

We Believe In

highest quality

service

At Vibra Finish, we pride ourselves on providing the highest quality service with the goal of increasing customer productivity and profitability. Our team will ensure that all parts are finished to meet and often exceed our customer’s expectations.

Create, innovate, educate

At the cutting edge of surface finishing technology, we are constantly innovating our processes to offer the best-suited solutions for your application. We have existing solutions that are proven in history for hundreds of customers. If an existing process doesn’t fit your needs, we will work with you to develop one that does. We take time to inform our customers about their options, while learning about their parts, and how they will be used, to best advise which process will suit their application.

Encourage, collaboration, teamwork & testing

We collaborate and partner with you to optimize your process. Our 360-degree teamwork is the foundation of our success. We work with you to develop a specifically catered process, through discussions and sample-part testing.

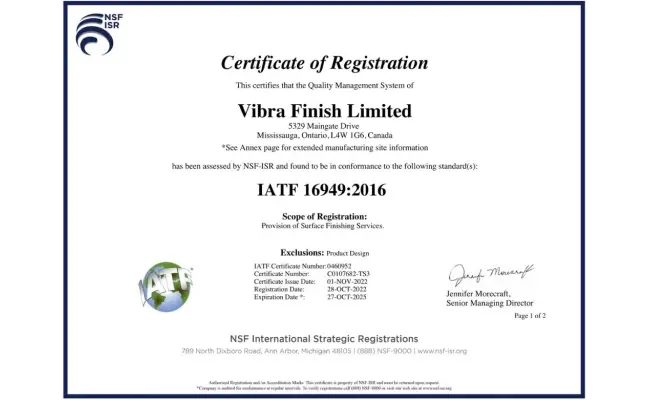

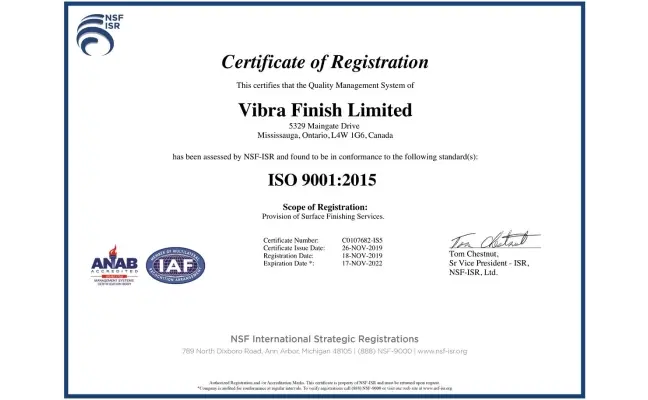

We Hold These Certifications

Our Valued Partnerships

In the past 30 years, KYZEN has proven over and over that scientific excellence and innovative solutions can be achieved by caring and persistently curious people. “Scientific excellence is important, but it is not enough all by itself! Mike and I believe placing great value in our people all while having fun is what makes the difference in our industry and in people’s lives.” says Doyel. This really is where science and care converge – and that makes all the difference.

Now, KYZEN is celebrating three decades and a global success story as leader in creating environmentally responsible cleaning solutions and innovations for electronics assembly, metal finishing and advanced packaging.

This growth is the direct result of its unique culture and approach to the convergence of science and care. KYZEN uniquely understands the risks, takes on the big commitments and delivers with high-energy people, scientific excellence and the resources needed, all while MAKING A DIFFERENCE in the lives of people.

The simple industrial wastewater treatment & equipment specialists. Moonstone is the fast and simple solution to eliminate your industrial wastewater issues in a matter of minutes. Moonstone’s unique, continuous automated flow-through systems utilize our custom-blended Reactive Separating Agents (RSAs) to simplify the treatment of your industrial wastewater. Our systems are ideal for removing suspended solids, emulsified oils, dissolved metals and many other types of contaminants from your wastewater, servicing the need for industrial wastewater treatment in a variety of processes. Each of our environmentally beneficial systems enable even the smallest of facilities to treat wastewater streams at a fraction of the cost of larger, more complex industrial systems, providing an immense cost savings to our domestic and international customers.

Jenfab is one of the largest parts washer manufacturers in the United States. We build custom machines across industries and offer an extensive standard equipment line. Our experts tackle cleaning challenges with innovative ideas and matchless machine quality.

Jenfab Cleaning Solutions was founded in 1960—the year of Muhammad Ali’s first professional fight, Alfred Hitchcock’s “Psycho,” the establishment of the Dallas Cowboys and John F. Kennedy’s presidential election. Our first machine was a cleaning system for rocket rails. (Did we mention the Space Race?) In 1962, our company was awarded a contract to manufacture shipping cradles for the fuel rails used in the Saturn V Missile. How were these aluminum fuel rails going to be cleaned before shipping? At the time, cleaning metal parts with chlorinated solvents, such as mineral spirits (IFI) and trichloroethylene (TCE), was the standard. Yet because of the product’s nature, it was decided that an aqueous solution made of alkaline cleaner and water would be better. Jenfab fabricated its first cleaning system for the missile’s fuel rails in 1963. After that project, the business shifted from welding fabrication to building aqueous parts washing systems. By 1967, Jenfab was primarily building parts washers.

Vibra Finish has been a supplier/collaborator with the University of Polytechnique, Montreal since 2015. We have engaged in several research projects, exploring the effects of peening on different materials using non-conventional techniques. This research has led to positive results that we believe will have a significant impact on how aerospace and industries with related needs will handle the peening requirements of their components in the future.

“From the success of the previous collaboration, as of January 1st, 2024, Vibra Finish Limited and the University of Polytechnique, Montreal will be partnering on a scientific research program with industry leaders in the aerospace community to further develop these new technologies and explore how best to implement these developments in to practical use”. - Zach McGillivray

Safran is the world's oldest aircraft engine manufacturer. The Group has built its history on iconic aerospace and defense companies, such as Snecma, Sagem, Labinal, Messier, Hispano-Suiza, Turbomeca and Zodiac. The ability to evolve and invent is at the heart of Safran's DNA, emphasized by series of major innovations along its whole history.

Vibra Finish has been partnering with Safran since 2018 in collaboration with Polytechnique Montréal, on the development of innovative, non-conventional peening techniques. Vibra Finish takes pride in contributing to the aerospace industry by continuously improving processes to be more environmentally friendly, while also enhancing logistical and cost efficiency. The combination of machinery manufacturing skills, technical knowledge, decades of industry experience and a customer-first approach makes the research projects conducted by Vibra Finish, Polytechnique Montréal, and Safran a seamless synergy, and a trifecta for success.”

Meet Our Team

Brian McGillivray

Chairman

Zach McGillivray

President

Clive Graham

Production Manager

Sheetal Patel

Manufacturing Manager

Dwayne Perry

Sales Manager

Bethany Groat

Quality Manager

Borhan Tehrani

Sales Engineer

John Van Eerde

Materials Manager

Dr. Maxime Paques

R&D and Peening Specialist

Our Story

- Joined the Canada Controlled Goods Program." Include CGP certificate.

- Constructed a large part-capacity shot blasting room (dimensions: 22X20X18 ft).

-

Started manufacturing machines

Started manufacturing machines

-

Opened job shop

Opened job shop

-

Began blending our own chemistry / compounds

Began blending our own chemistry / compounds

-

Plant 2 Opened

Plant 2 Opened

-

Plant 3 Opened. Offered parts washing services. Phased out rotary and introduced high efficiency vibe tumblers.

Plant 3 Opened. Offered parts washing services. Phased out rotary and introduced high efficiency vibe tumblers.

-

Plant 4 Opened

Plant 4 Opened

-

ISO Registered

ISO Registered

-

Began to offer blast resistant part masking

Began to offer blast resistant part masking

-

Began to offer shot peening services

Began to offer shot peening services

-

Integration of automation, barcoding

Integration of automation, barcoding

-

Automated Vision System

Automated Vision System

-

Began manufacturing belt / drum driers

Began manufacturing belt / drum driers

-

IATF Certification

IATF Certification

-

AS9100 Certification

AS9100 Certification

-

Controlled Good Certification

Controlled Good Certification