Military Standards and Specifications for Shot Peening

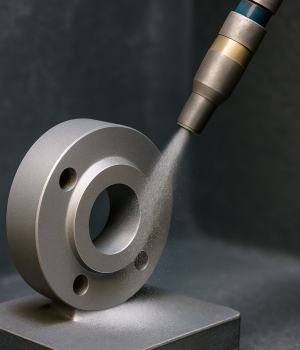

In the military world, good enough doesn’t cut it. Shot peening must meet strict specs like AMS 2430, MIL-S-13165, and NADCAP accreditation standards. These guidelines dictate acceptable media, coverage uniformity, intensity range, and even masking protocols to protect non-target areas.

Inspections include saturation curve testing, Almen strip measurements, and visual verifications. The saturation curve defines the intensity and peening time required for effective stress transformation. Almen strips are precision test strips placed in peening chambers to measure deformation, indicating if compressive stress has been properly achieved.

Military contractors must regularly calibrate their equipment, validate media consistency, and train operators to interpret results accurately. Compliance isn’t just paperwork—it’s performance assurance in high-stakes environments where margin for error is zero.

Case Studies: Shot Peening Success in Military Aviation and Armor

Let’s talk results. One notable case study involves F-16 fighter jets. After incorporating shot peening into the landing gear overhaul process, engineers noted a 3x increase in fatigue life. That meant fewer part replacements, increased mission availability, and lower operational costs.

Another case: armored personnel carriers deployed in high-impact zones. Traditional armor plates suffered from rapid cracking and surface erosion. But once peening was applied to weld zones and stress concentration areas, field failure rates dropped by over 40% within the first 18 months.

Even small UAV components—often overlooked—have shown dramatic durability improvements. In one test, drone rotor hubs subjected to peening lasted 2.5x longer during aggressive wind tunnel testing compared to untreated counterparts. That’s the kind of edge modern warfare demands.

How Shot Peening Compares to Other Surface Enhancement Techniques

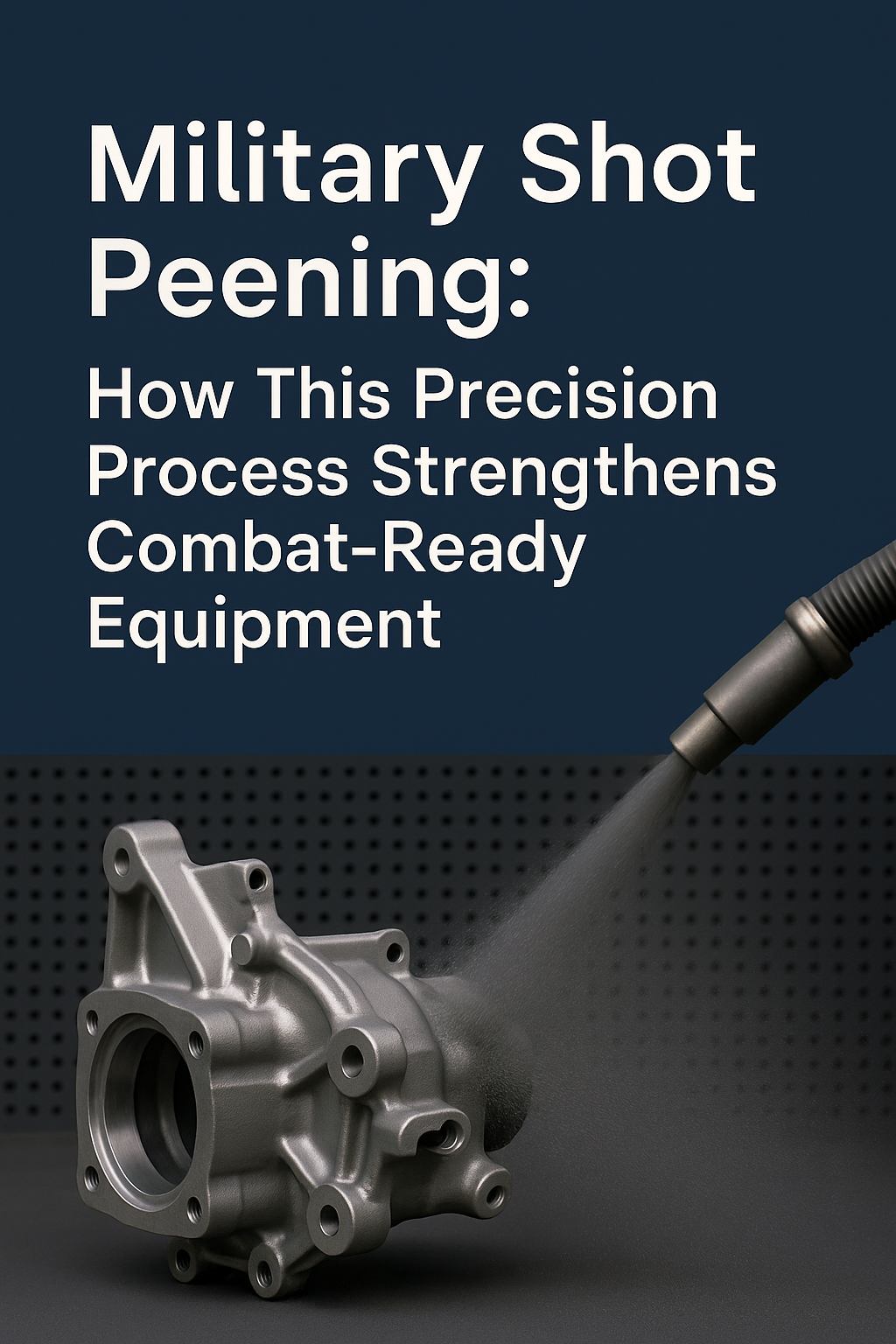

Now, you might be wondering: how does shot peening stack up against other treatments like heat-treating, laser shock peening, or carburizing? Here’s the scoop—each method has its niche, but shot peening offers unmatched simplicity, repeatability, and cost-effectiveness for mass treatment.

Laser peening provides deeper compression layers but requires expensive, energy-intensive setups. Heat treatment can alter material properties in bulk but lacks the precision control that shot peening offers for surface-only modification. Carburizing is great for hardness but doesn’t address fatigue the same way compressive stress does.

For aerospace and ground combat applications, shot peening remains a go-to because it can be tightly localized, automated, and verified without altering the component’s core properties. It’s tough to beat that blend of performance, safety, and scalability.

Challenges in Implementing Shot Peening Across Military Manufacturing

Despite its benefits, shot peening isn’t a plug-and-play solution. One challenge is process standardization across suppliers. Even slight differences in shot size, angle, or coverage can lead to inconsistencies—especially on complex geometries like turbine blades or curved armor panels.

Another hurdle is media contamination. Foreign particles in the media stream can introduce surface flaws instead of fixing them. That’s why modern systems use closed-loop filtering and particle counters to ensure purity. Still, it’s an area that demands vigilance.

Lastly, training remains a bottleneck. Shot peening is part art, part science, and operators need to interpret data, adjust for geometry, and troubleshoot on the fly. As automation becomes more prevalent, human oversight remains crucial to quality assurance.

The Future of Military Shot Peening and Advancements in Automation

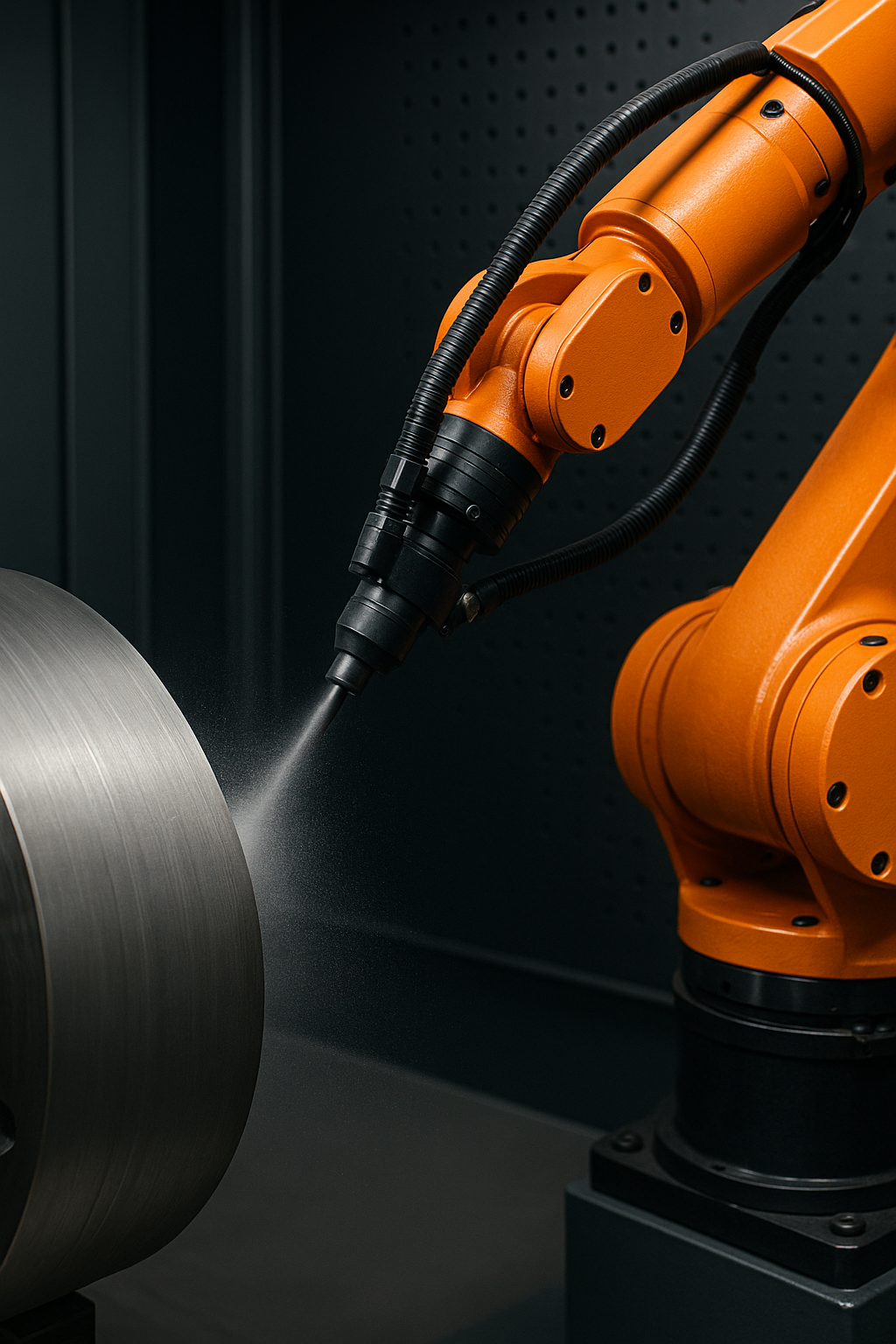

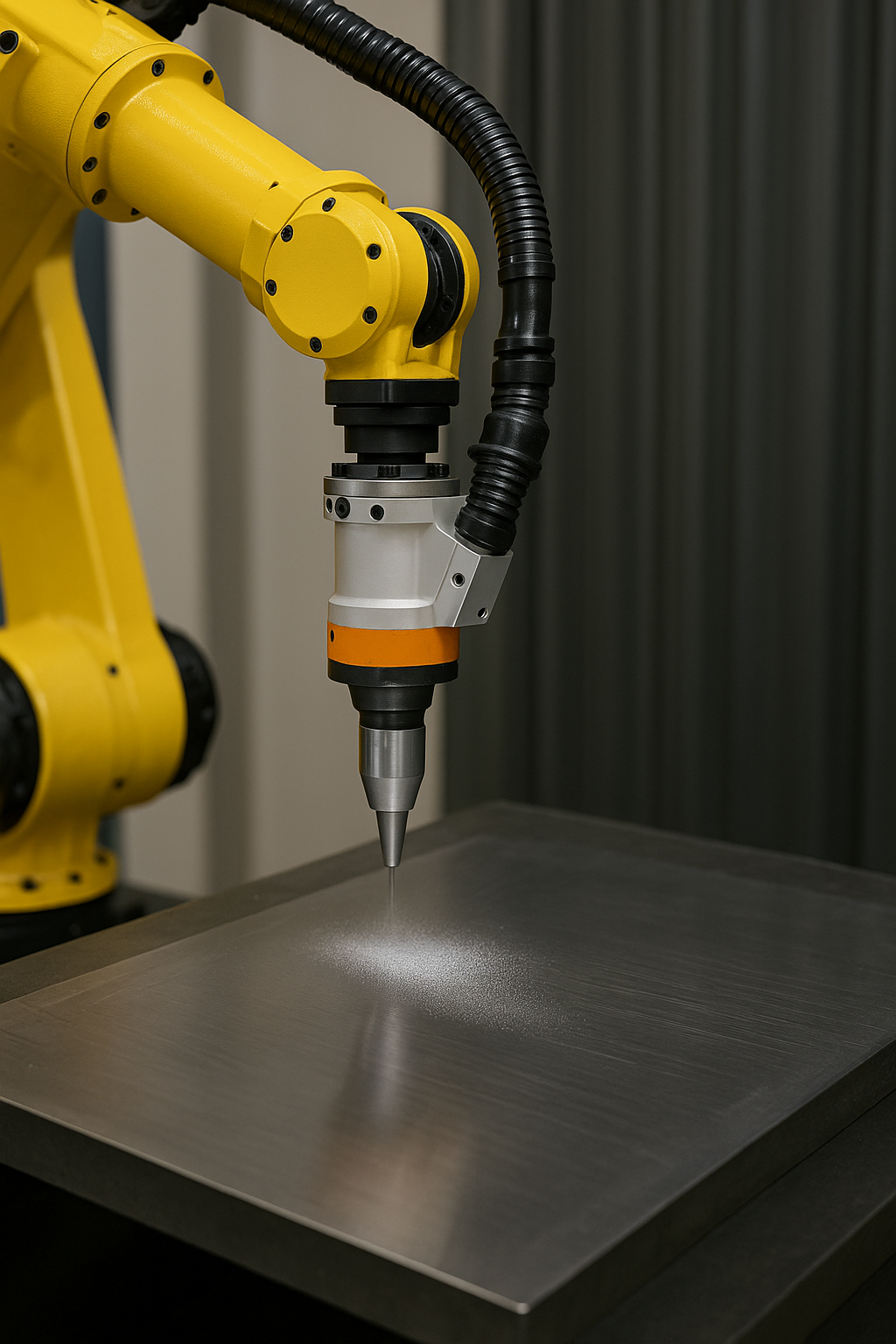

Looking ahead, military shot peening is going digital. Advanced robotics, real-time sensor feedback, and AI-driven process control are pushing the envelope. Imagine a smart peening arm that adjusts intensity based on live surface feedback—that’s already in prototype stages for aerospace use.

Additive manufacturing is another area to watch. As 3D-printed titanium and metal alloys become more common, shot peening will evolve to accommodate their unique microstructures. Specialized media types and peening patterns will likely emerge to address these futuristic materials.

Lastly, sustainability is entering the scene. Recyclable media, low-emission enclosures, and energy-efficient compressors are becoming standard features. Because yes, even the military is working toward greener manufacturing processes—and shot peening is ready to adapt.

Conclusion

Military shot peening might not get flashy headlines, but it’s one of the unsung heroes of defense engineering. From improving structural integrity and extending part lifespan to keeping aircraft and armor battle-ready, this precision process plays a critical role across every branch of the military.

As technology evolves and equipment demands intensify, shot peening will continue to adapt—bringing more automation, better materials, and smarter control systems. Whether you’re an engineer, a defense contractor, or just a curious mind, understanding this technique gives you a deeper appreciation for the engineering behind the scenes.

If this article gave you a new perspective on how shot peening supports military resilience, share it with a colleague, leave a comment with your thoughts, or subscribe for more insights into the tech behind the gear.