Modify a Horizontal Barrel Tumbler

Aside from using trim dies, the usual method of degating is to tumble in an open mouth oblique barrel then screen separate the parts. Working with small pieces in very large barrel tumblers means a densely packed load that is too heavy to move easily and has poor flow properties. Too much time is spent moving and screening the parts. One solution is to alter a standard horizontal enclosed barrel tumbler by adding an extra large door opening. The load is then tumble-degated. This process also removes flash and polishes. The solid door can then be removed and replaced by a screen door. As the barrel rotates, the parts fall out, leaving all the gates in the barrel. The parts are degated, deflashed and separated at one station, completely eliminating moving the parts.

This type of unit can also solve another problem that often plagues die-casters when working with small parts. The sprue and runner must be kept on the screen as the parts go through and the sprue often covers or fills in the holes. Since the sprue is heavy, it usually cannot be bounced out of the holes again. The rotating barrel eliminates this problem because it empties the hole every time it revolves.

Use an Oblique Tilting Tumbler

This principle can also be applied to the oblique (tilt) tumbler. Locks can be added to the mouth of the barrel to clamp on a screen door. The barrel is loaded then the screen door is put in place. The barrel is run at a 45º upward tilt until the pieces are broken off and smoothed out. The barrel is then tilted down 45º, bringing the load forward to the screen. This is a good solution if you already have tilt tumblers, but if a choice can be made, the horizontal barrels will prove faster and more thorough. It should be noted that if a machine has bronze bearings instead of roller bearings, the bronze bearings would need copious lubrication to handle the extra load. Slotted screens or parallel bars have proven successful in allowing thin parts such as loops or zipper pulls to fit through while holding back the thicker gate.

Other Considerations

Generally, barrel tumblers are run at a high surface feet per minute (SFPM) rate – approximately 250-300 SFPM. Do not add more fins for more aggressive action. Adding fins will shorten the cycle, but they can severely damage the surface of the parts and close up holes. It is better to increase the speed to get a shorter run.

When planning molds, always minimize the thickness of the sprue at the point of junction. The best configuration is a smooth radius or taper rather than a notch or step. Width is not critical, but thickness is, for a good clean break. The parts should be cool for this type of degating. Warm parts are not brittle enough for a clean break. Temperature should be considered when planning an automated line.

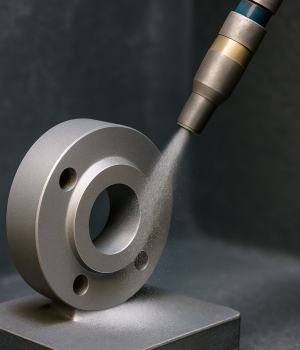

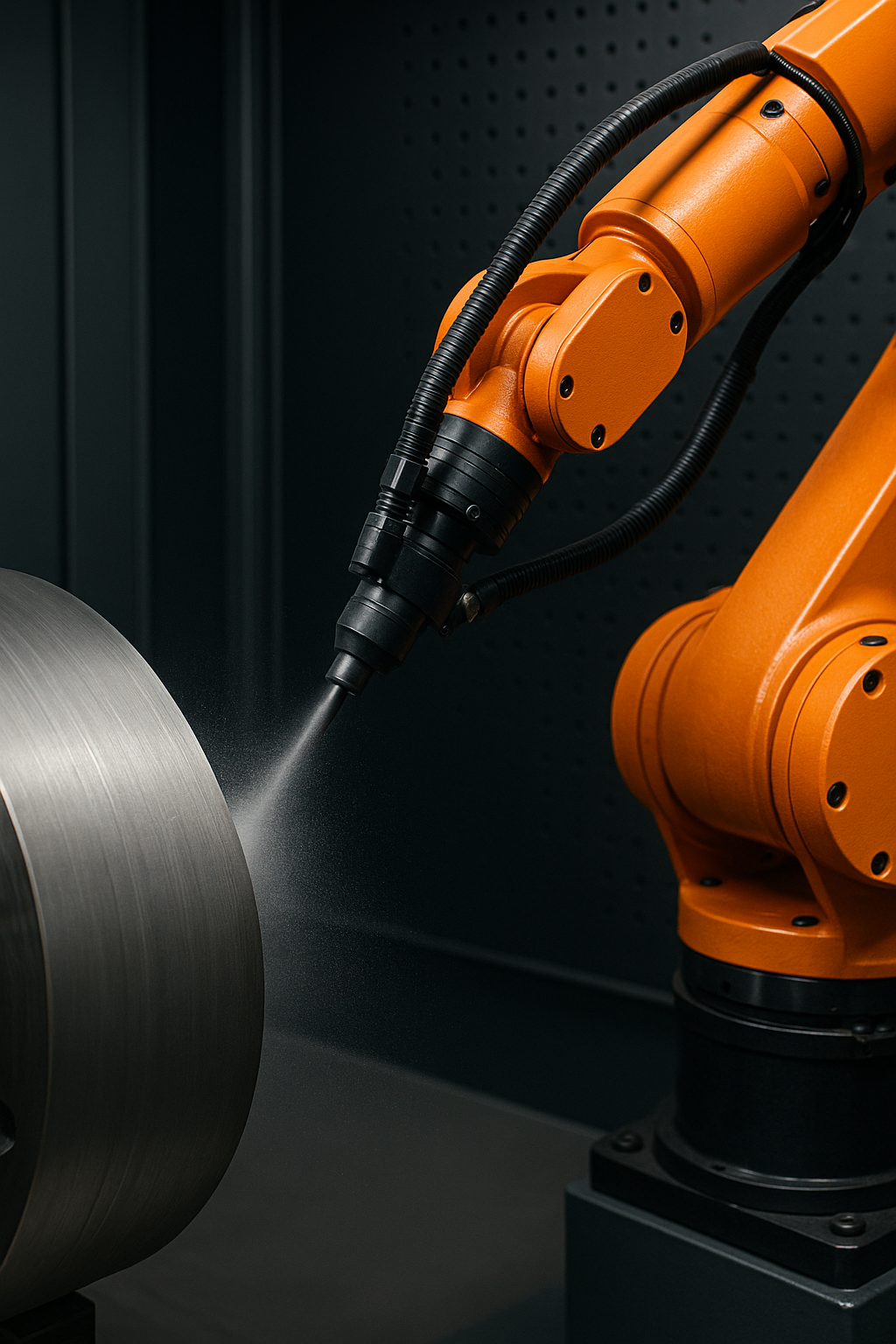

Sometimes flash is in an area where self-tumbling or tumbling parts in media will not remove it. If the parts are run in a screen basket in a sandblaster using glass shot, flash can be removed from every crevice without worrying about crushing a fragile part.

Separating Parts from Media

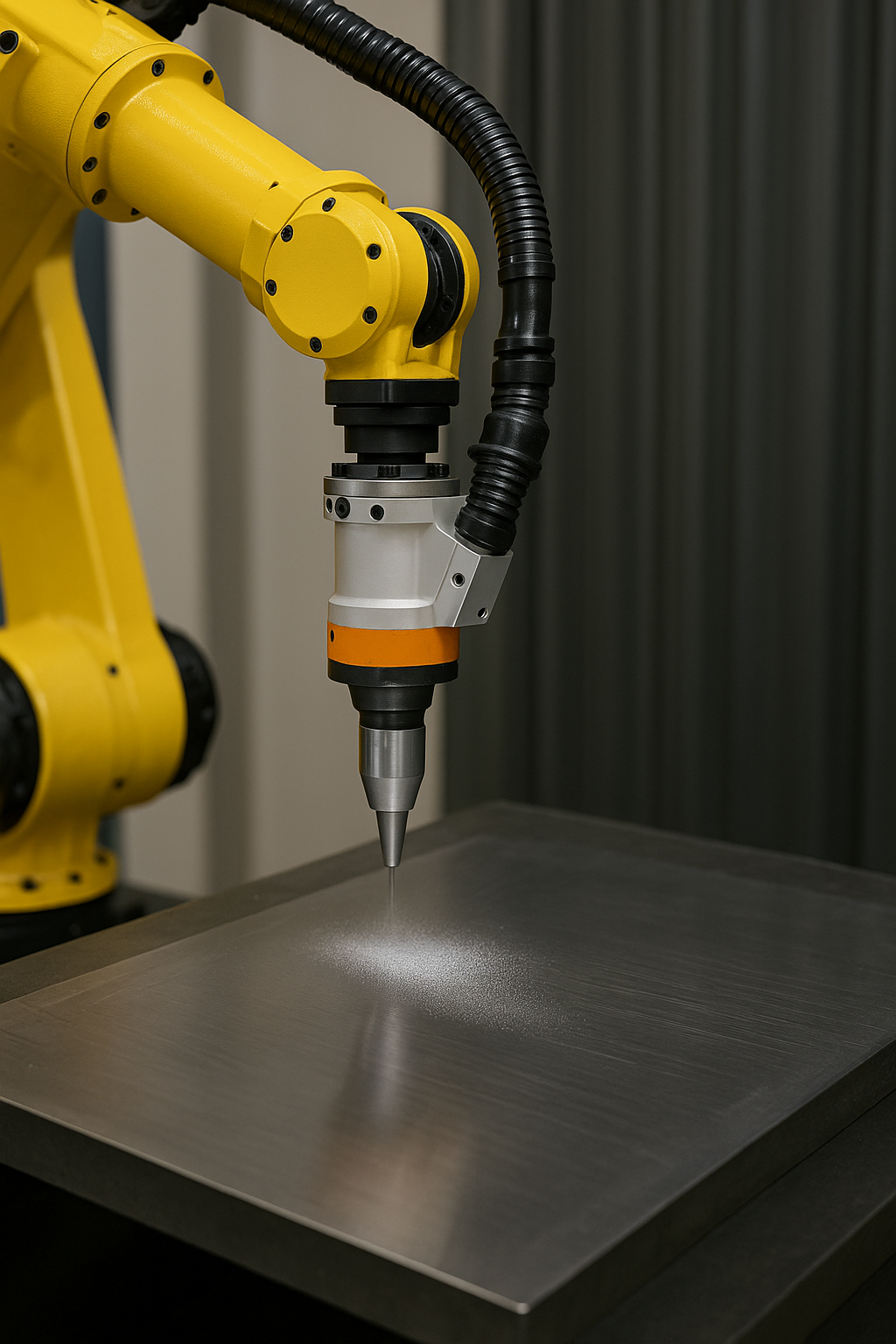

There are various machines that are built specifically for the separation operation. One such type has a set of rollers at a slight angle to each other. The rollers rotate counter to each other, spinning the parts to give them a chance to fall through the gap. The gap widens as they move down and each part falls through at the appropriate point. This type of system is very good for small parts that are thinner than the sprue, but cannot handle a large volume of parts.

Large parts can be handled in any volume using a drop-off screen. These are vibrating screens that feed the load to the far end, dropping the scrap through the screen. The parts drop off the end into catch pans. These systems work better than batch screens, where parts can cover the holes. The rotation is utilized to keep the screen clear. The parts feed off the top of the screen while the tabs and scrap fall through into a bin. This type of unit can fit into an automated line.

One thing to remember: it is simpler to plan your shot selection to provide for easy separation from parts when making the mold than to set up elaborate separation equipment later.