We are happy to announce that Vibra Finish Ltd is now certified IATF 16949:2016. Certificate of Registration: This certifies that the Quality Management System of Vibra Finish Limited, 5329 Maingate Drive, Mississauga, Ontario, L4W 1G6, Canada has been assessed by NSF-ISR and found to be in conformance to the following standard(s): IATF 16949:2016. Scope of Registration: Provision of Surface Finishing Services. Expiration date: October 27, 2025.

Vibra is Now Certified IATF 16949:2016

Vibra is Now Certified IATF 16949:2016

You May Also Like

Metal Shot Peening Services

Metal Shot Peening Services That Instantly Boost Part Strength—Here’s Why Engineers Swear By It

Metal shot peening services aren’t some industrial sorcery—they’re just wildly effective, and everyone from aerospace giants to custom bike builders is in on it. You might not think much about what keeps aircraft components flying or race car engines running smoother for longer, but chances are, this gritty little technique had a role.

Like anything worth trusting, metal shot peening doesn’t rely on flash. It works because physics says so. Tiny metallic shots bombarding the surface? Sounds harsh—until you realize they’re actually strengthening the part with every hit.

You see, when it comes to reducing stress fatigue and extending metal life, this method delivers results quietly and consistently. And in a world that’s constantly evolving, leaning on proven techniques like metal shot peening services just makes sense. So let’s peel back the layers.

What is Metal Shot Peening and How Does It Work

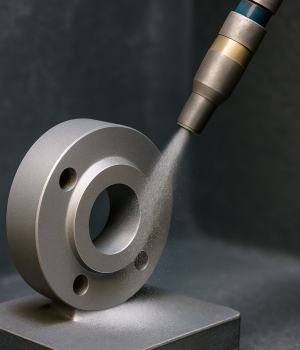

Metal shot peening is a cold working process where tiny spherical media (usually steel, ceramic, or glass beads) are blasted onto a metal surface at high velocity. Each microscopic impact leaves a small indentation—or dimple—on the surface, creating a beneficial layer of compressive stress.

This residual compressive stress is key. It counteracts the tensile stress that often leads to fatigue cracks and part failure. Over time, these compressive layers form a kind of invisible armor that helps metal parts withstand repeated use, vibration, and bending forces.

What’s neat about shot peening is that it doesn’t alter the part’s shape or size. It enhances durability without compromising precision—making it ideal for aerospace, automotive, and medical components that demand strength without distortion.

Core Benefits of Using Metal Shot Peening Services in Manufacturing

First off, fatigue resistance. Metal components are always battling fatigue from repeated stress—think jet turbine blades or transmission gears. Shot peening significantly increases their lifespan by creating that stress-buffering compressive layer.

Second, there’s improved surface hardness. This can be a game-changer for wear-prone parts like springs, shafts, and gear teeth. They last longer and resist corrosion better thanks to the work-hardening effect of peening.

And let’s not forget the cost-benefit ratio. Replacing failed components costs way more than preventing failure in the first place. That’s where shot peening services shine—it’s a preventative upgrade, not just a repair tactic.

Industries That Rely Heavily on Shot Peening for Performance

Aerospace is probably the most high-stakes example. From landing gear to engine turbines, shot peening is standard protocol to maintain safety and structural integrity across thousands of flight hours.

Automotive industries use shot peening to increase the durability of critical parts like valve springs, gears, and crankshafts. It enhances performance under load, which is essential in high-performance engines and off-road vehicles.

Energy sectors—especially wind turbines and oil drilling—rely on peened components that can resist fatigue and corrosion in extreme environments. Even the medical field uses it for surgical implants and instruments requiring exact tolerances and high wear resistance.

How Shot Peening Compares to Other Surface Finishing Techniques

Unlike abrasive blasting or polishing, metal shot peening doesn’t just “clean” the surface. It changes the mechanical properties without affecting shape or dimensions. That’s a huge advantage in precision engineering.

Compared to coatings or plating, peening doesn’t rely on an external material layer that could chip, peel, or degrade. The benefits are baked right into the metal itself through compressive stress—no add-ons required.

Laser peening and ultrasonic peening are similar in outcome, but they often require higher cost and more complex equipment. Shot peening remains the most accessible and scalable solution for mass production environments.

The Science Behind Residual Stress and Fatigue Resistance

Think of residual stress like the cushion that absorbs shock. When parts are under tension (like a wing during flight), the preloaded compressive stress from shot peening counteracts those forces and keeps microcracks from forming or growing.

This is especially useful in parts exposed to cyclic loading. Without compressive stress, the metal surface is vulnerable to crack initiation—something you definitely want to avoid in aircraft or rotating machine parts.

The real genius of shot peening is that it turns stress into strength. By modifying the internal stress field, it literally reshapes how the part reacts under pressure—without a single bolt or weld involved.

Choosing the Right Media and Intensity for Peening Processes

Media selection is not one-size-fits-all. Steel shot is durable and great for heavy-duty parts. Ceramic media works well for applications requiring cleanliness and non-ferrous compatibility. Glass beads are often used where aesthetics matter too.

Intensity refers to the force and coverage of the impact. Too low and you won’t get sufficient stress. Too high and you risk damaging the surface or inducing unwanted deformation. That’s where Almen strips come in—they help measure and standardize intensity levels.

The right combination depends on material type, part geometry, and operational stress factors. This is why expert metal shot peening services matter—they tailor each process to the part, not the other way around.

Common Metals Treated with Shot Peening and Their Outcomes

Steel alloys are the most common candidates. High-stress components like springs, axles, and gears benefit massively in terms of fatigue resistance and surface hardness after peening.

Aluminum parts—often used in aerospace—are more delicate but still benefit from controlled peening. It improves fatigue life without adding weight, which is critical for flight dynamics.

Titanium and Inconel—found in jet engines and high-temp environments—also respond well. Shot peening reduces oxidation sensitivity and enhances overall structural performance under extreme conditions.

Quality Control and Standards in Shot Peening Services

Reputable metal shot peening services follow strict industry standards like SAE J442 or AMS 2430. These regulate intensity, coverage, media type, and verification techniques like Almen testing.

Documentation and traceability are also key. Every shot-peened part should come with a quality report verifying parameters met or exceeded industry tolerances. That’s how you know it’s not just a “blast and go” service.

In sectors like aerospace and automotive, quality control isn’t just best practice—it’s legally required. Failure to meet specs can lead to major liability and catastrophic failure, so QC is baked into every step of the process.

Technological Innovations in Modern Shot Peening Equipment

Automated shot peening machines with robotic arms are now standard in many industries. They ensure consistent coverage and intensity, even for complex part geometries like turbine blades or camshafts.

Advanced monitoring systems can track every shot’s velocity and angle in real-time. This kind of feedback ensures the process stays within tight parameters, improving both reliability and repeatability.

Other advancements include dual-media systems, which allow switching between media types without halting operations, and environmentally friendly recovery systems that reduce waste and contamination risks.

Cost vs. Value Analysis of Investing in Shot Peening Services

Yes, shot peening services have upfront costs. But when weighed against the value—extended part life, fewer failures, better performance—the ROI is undeniable. It’s a classic “pay now or pay more later” equation.

For OEMs, reducing warranty claims alone can justify the cost. For aerospace and defense, reliability is worth its weight in gold. Even small-scale manufacturers benefit from longer tool life and reduced downtime.

Plus, it’s more affordable than some alternatives like coatings, which require reapplication, or part redesigns, which cost time and engineering resources. Peening is a cost-effective insurance policy for any metal part under stress.

Conclusion

All things considered, metal shot peening services are one of the most underrated champions of industrial reliability. From boosting fatigue resistance to improving surface hardness and ensuring part longevity, shot peening offers measurable, science-backed results across industries. And it does all this without altering part dimensions or relying on chemical coatings.

We’ve unpacked how it works, why it matters, and how to make it work for you. Whether you’re dealing with aerospace components, automotive parts, or high-performance tools, shot peening deserves a front-row seat in your production or maintenance process.

Ready to give your metal parts a serious durability upgrade? Leave a comment below, share this post with your engineering team, or subscribe to our newsletter for more deep dives into proven performance techniques.

Military Shot Peening

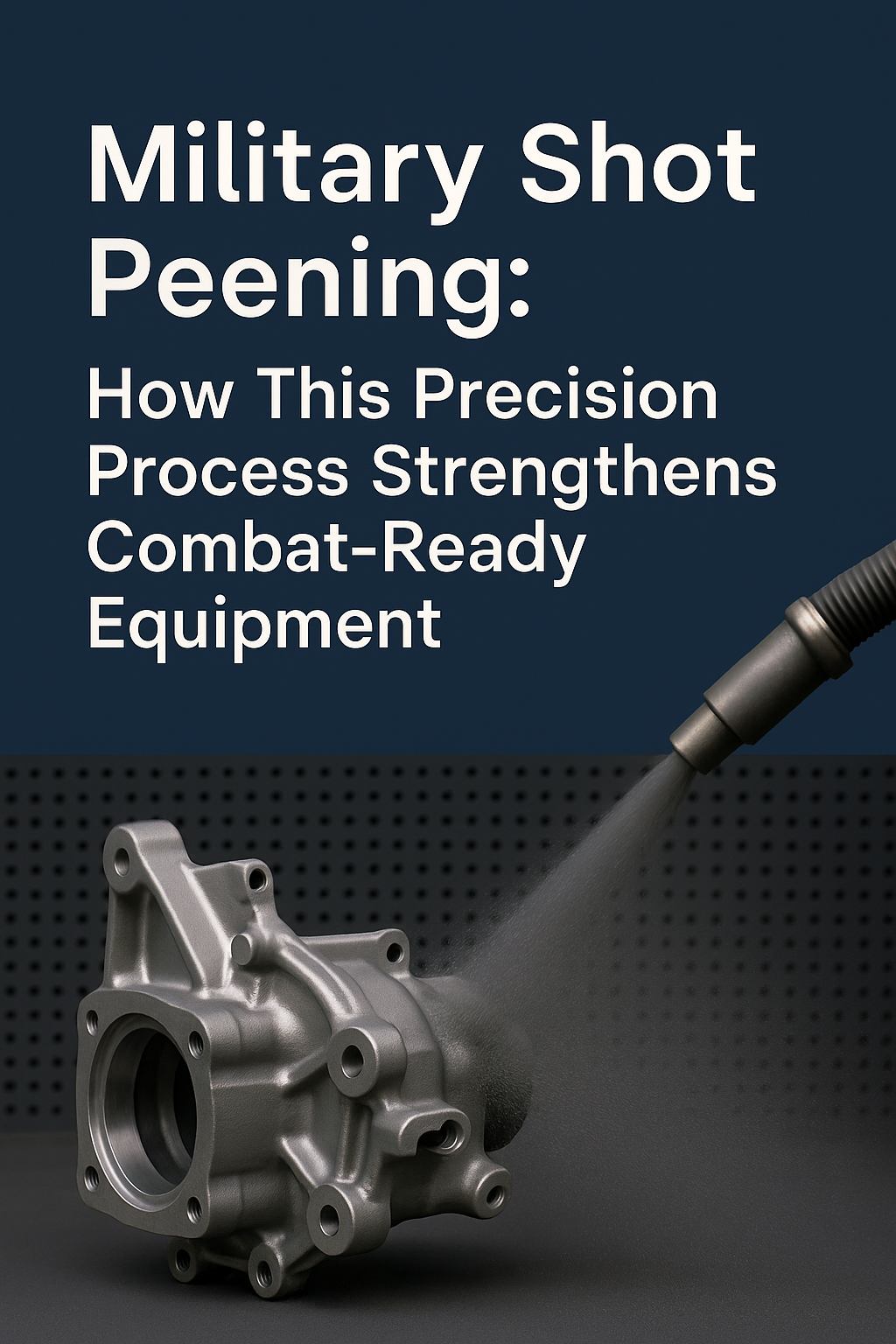

Military Shot Peening: How This Precision Process Strengthens Combat-Ready Equipment

Understanding the Fundamentals of Military Shot Peening

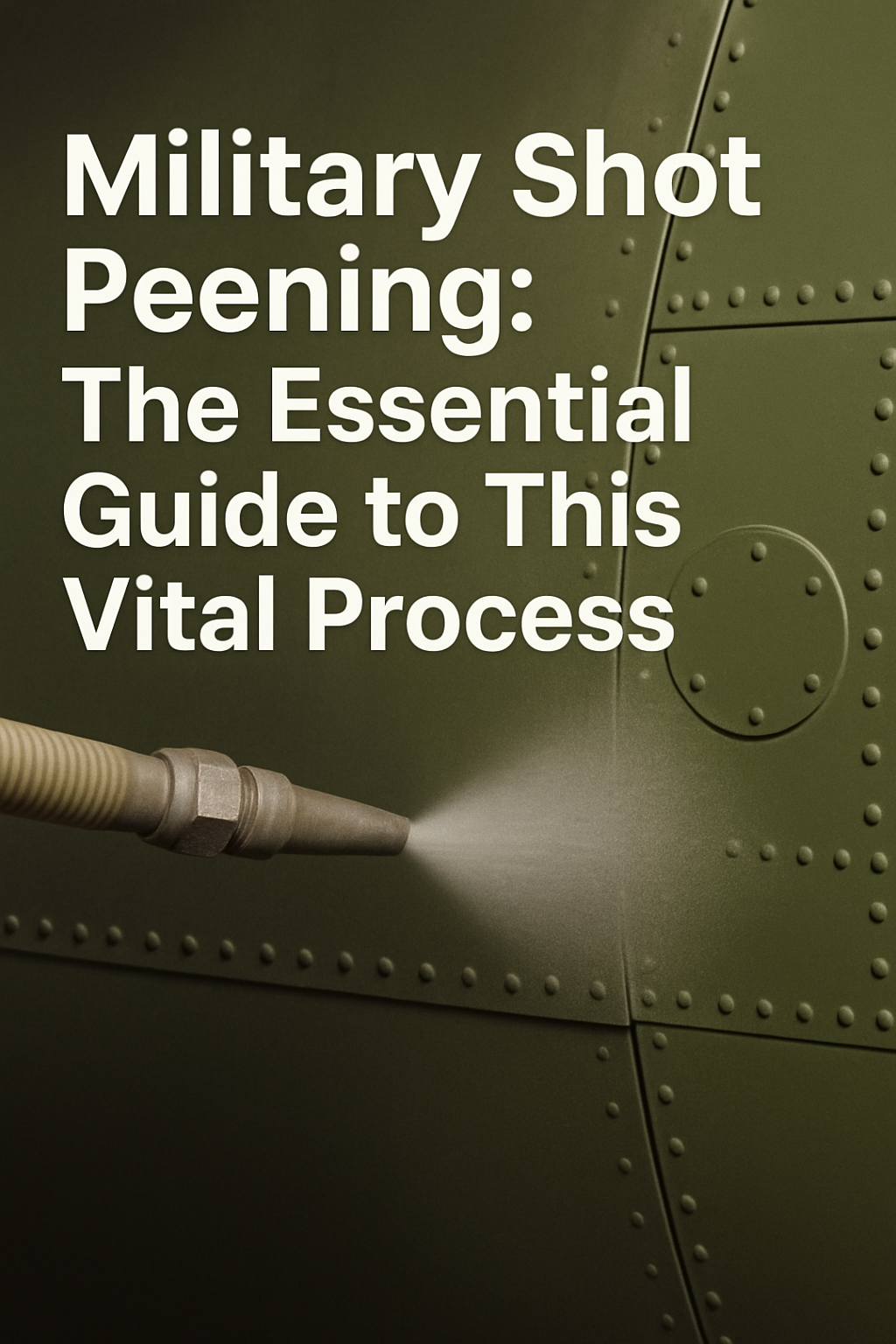

Military shot peening is more than just a surface treatment—it’s a science-backed defense tactic. Essentially, it involves bombarding metal surfaces with tiny spherical media to introduce compressive stress. This seemingly simple process plays a vital role in preventing microscopic cracks from growing into catastrophic failures. And when it comes to mission-critical gear, there’s no room for structural weaknesses.

What sets military shot peening apart from regular industrial methods is the precise calibration. The intensity, coverage, and media type are carefully controlled to meet strict defense standards. Unlike decorative or light industrial peening, military applications require deeper surface engagement and consistent results across complex geometries.

You see, while the idea of “controlled dents” might sound counterintuitive, this intentional damage actually strengthens the material. It creates a surface compression layer that resists fatigue, corrosion, and stress fractures—essential for military aircraft, naval components, and armored vehicles that face constant environmental and operational pressure.

How Shot Peening Enhances Structural Integrity in Defense Applications

One of the most compelling benefits of military shot peening is its ability to dramatically improve structural integrity. In fact, this process is often the difference between a component that endures and one that fails mid-mission. By introducing a beneficial compressive stress layer, shot peening mitigates the effects of tensile stress, which typically leads to cracks and fatigue over time.

In environments where vibration, torque, and pressure are the norm—not the exception—every extra ounce of durability counts. This is especially true for landing gear components, engine parts, and rotor blades. These parts are regularly exposed to extreme mechanical loads, and without shot peening, their lifespan would be significantly shorter.

Shot peening doesn’t just prevent failure—it enables consistent performance over time. A helicopter rotor treated with this technique will endure thousands of stress cycles without cracking, while untreated ones may suffer fatigue failure well before scheduled maintenance. That’s the kind of impact only strategic surface treatment can deliver.

The Role of Shot Peening in Extending Equipment Lifespan

Military budgets aren’t infinite, and neither is equipment. Extending the operational life of parts without compromising safety is a top priority—and that’s where shot peening comes in. By shielding parts from fatigue and surface deterioration, this method keeps systems mission-ready for longer periods, reducing the need for frequent overhauls or premature replacement.

Let’s take a practical example: turbine blades in fighter jets. These components experience constant high-velocity impacts and intense thermal stress. Shot peening helps maintain their strength and geometry far beyond standard cycles. It’s not uncommon for treated parts to double their service life—sometimes more—with proper application.

Longer life cycles also mean less downtime and lower logistical costs. When parts last longer and perform better, crews spend less time in the shop and more time on the field. That’s a win for readiness, efficiency, and budgetary planning.

Common Military Components That Undergo Shot Peening

So, which components benefit most from this treatment? The answer: almost anything metal that’s under stress. High-value and high-impact parts like aircraft landing gear, missile housings, gearbox components, drive shafts, armor plating, gun barrels, and even jet engine disks are routinely shot peened before deployment.

In naval applications, propeller shafts, rudder linkages, and deck mechanisms also undergo shot peening to resist salt-induced corrosion and fatigue from turbulent water dynamics. In land vehicles, transmission gears, springs, axles, and armor panels benefit significantly from this process, especially when terrain-induced vibration is a constant factor.

Even lightweight drone parts—typically made from aluminum or titanium alloys—are peened to ensure aerodynamic reliability and resistance to atmospheric wear. If it moves, rotates, takes a hit, or bears weight in military equipment, there’s a high chance shot peening has touched it.

Types of Shot Peening Media Used in Military-Grade Applications

Not all shot is created equal. The media used in military shot peening varies based on the base material and required performance. Common types include cast steel shot, cut wire shot, ceramic beads, and glass beads. Each offers distinct benefits and trade-offs in terms of surface finish, penetration depth, and contamination risk.

For high-strength steels, cast steel and conditioned cut wire are preferred due to their density and kinetic energy. For softer metals or aerospace-grade aluminum, ceramic beads offer a lighter touch with better coverage uniformity. Glass beads are sometimes used where cosmetic finish and minimal surface distortion are priorities.

And let’s not forget automated media tracking. Modern shot peening setups often include automated flow control and feedback loops to monitor media breakdown, size uniformity, and contamination—because precision matters when lives depend on performance.

Military Standards and Specifications for Shot Peening

In the military world, good enough doesn’t cut it. Shot peening must meet strict specs like AMS 2430, MIL-S-13165, and NADCAP accreditation standards. These guidelines dictate acceptable media, coverage uniformity, intensity range, and even masking protocols to protect non-target areas.

Inspections include saturation curve testing, Almen strip measurements, and visual verifications. The saturation curve defines the intensity and peening time required for effective stress transformation. Almen strips are precision test strips placed in peening chambers to measure deformation, indicating if compressive stress has been properly achieved.

Military contractors must regularly calibrate their equipment, validate media consistency, and train operators to interpret results accurately. Compliance isn’t just paperwork—it’s performance assurance in high-stakes environments where margin for error is zero.

Case Studies: Shot Peening Success in Military Aviation and Armor

Let’s talk results. One notable case study involves F-16 fighter jets. After incorporating shot peening into the landing gear overhaul process, engineers noted a 3x increase in fatigue life. That meant fewer part replacements, increased mission availability, and lower operational costs.

Another case: armored personnel carriers deployed in high-impact zones. Traditional armor plates suffered from rapid cracking and surface erosion. But once peening was applied to weld zones and stress concentration areas, field failure rates dropped by over 40% within the first 18 months.

Even small UAV components—often overlooked—have shown dramatic durability improvements. In one test, drone rotor hubs subjected to peening lasted 2.5x longer during aggressive wind tunnel testing compared to untreated counterparts. That’s the kind of edge modern warfare demands.

How Shot Peening Compares to Other Surface Enhancement Techniques

Now, you might be wondering: how does shot peening stack up against other treatments like heat-treating, laser shock peening, or carburizing? Here’s the scoop—each method has its niche, but shot peening offers unmatched simplicity, repeatability, and cost-effectiveness for mass treatment.

Laser peening provides deeper compression layers but requires expensive, energy-intensive setups. Heat treatment can alter material properties in bulk but lacks the precision control that shot peening offers for surface-only modification. Carburizing is great for hardness but doesn’t address fatigue the same way compressive stress does.

For aerospace and ground combat applications, shot peening remains a go-to because it can be tightly localized, automated, and verified without altering the component’s core properties. It’s tough to beat that blend of performance, safety, and scalability.

Challenges in Implementing Shot Peening Across Military Manufacturing

Despite its benefits, shot peening isn’t a plug-and-play solution. One challenge is process standardization across suppliers. Even slight differences in shot size, angle, or coverage can lead to inconsistencies—especially on complex geometries like turbine blades or curved armor panels.

Another hurdle is media contamination. Foreign particles in the media stream can introduce surface flaws instead of fixing them. That’s why modern systems use closed-loop filtering and particle counters to ensure purity. Still, it’s an area that demands vigilance.

Lastly, training remains a bottleneck. Shot peening is part art, part science, and operators need to interpret data, adjust for geometry, and troubleshoot on the fly. As automation becomes more prevalent, human oversight remains crucial to quality assurance.

The Future of Military Shot Peening and Advancements in Automation

Looking ahead, military shot peening is going digital. Advanced robotics, real-time sensor feedback, and AI-driven process control are pushing the envelope. Imagine a smart peening arm that adjusts intensity based on live surface feedback—that’s already in prototype stages for aerospace use.

Additive manufacturing is another area to watch. As 3D-printed titanium and metal alloys become more common, shot peening will evolve to accommodate their unique microstructures. Specialized media types and peening patterns will likely emerge to address these futuristic materials.

Lastly, sustainability is entering the scene. Recyclable media, low-emission enclosures, and energy-efficient compressors are becoming standard features. Because yes, even the military is working toward greener manufacturing processes—and shot peening is ready to adapt.

Conclusion

Military shot peening might not get flashy headlines, but it’s one of the unsung heroes of defense engineering. From improving structural integrity and extending part lifespan to keeping aircraft and armor battle-ready, this precision process plays a critical role across every branch of the military.

As technology evolves and equipment demands intensify, shot peening will continue to adapt—bringing more automation, better materials, and smarter control systems. Whether you’re an engineer, a defense contractor, or just a curious mind, understanding this technique gives you a deeper appreciation for the engineering behind the scenes.

If this article gave you a new perspective on how shot peening supports military resilience, share it with a colleague, leave a comment with your thoughts, or subscribe for more insights into the tech behind the gear.

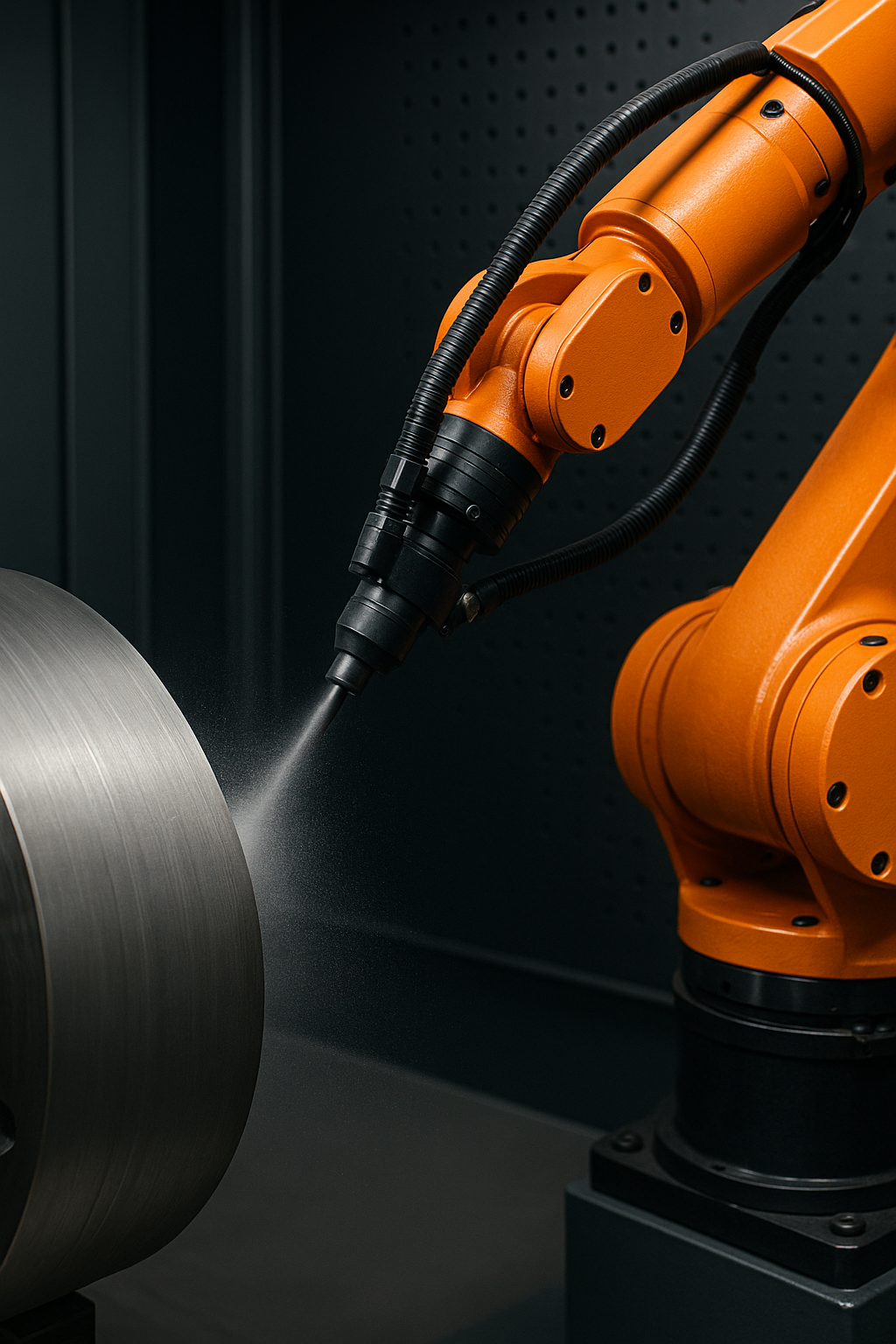

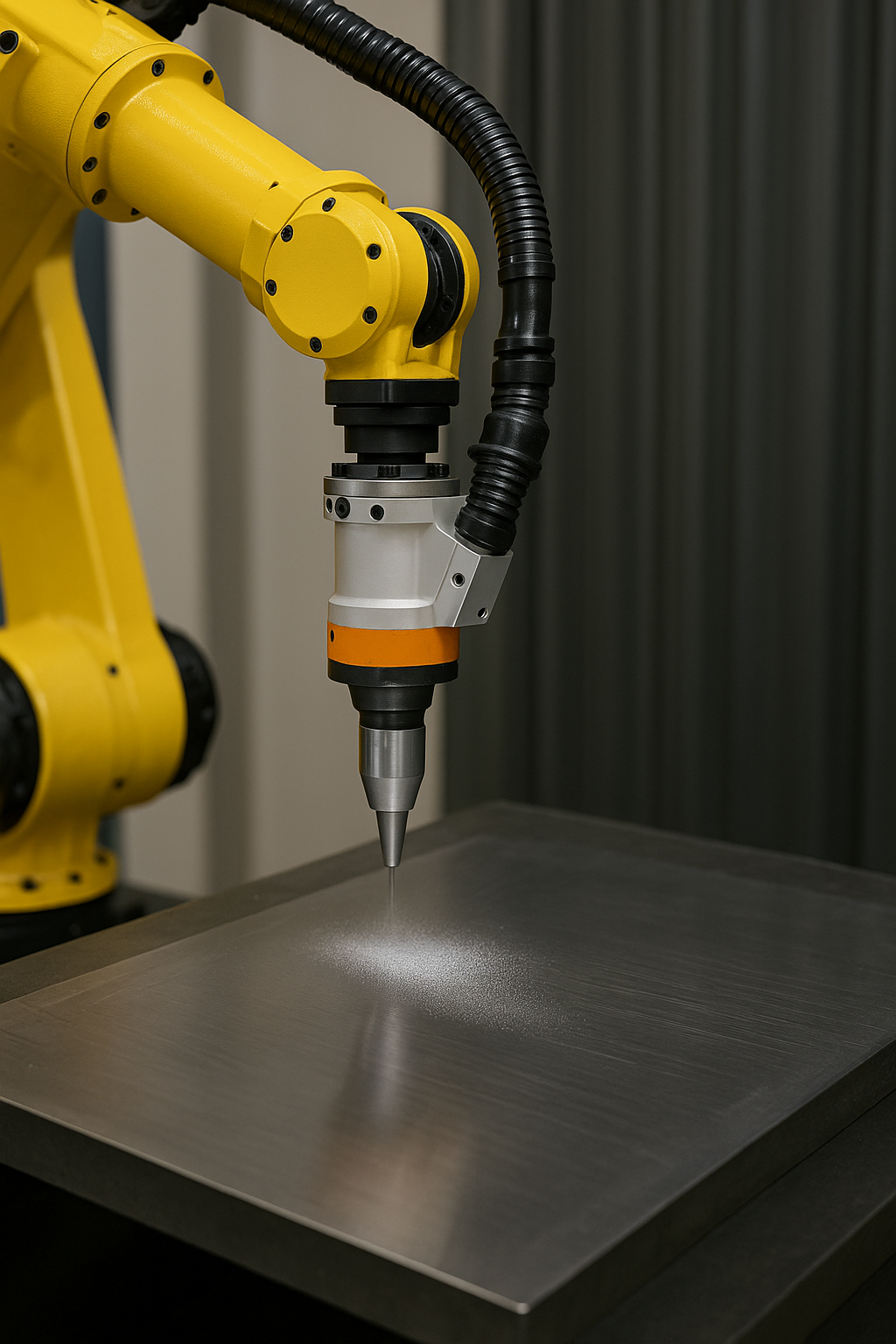

Robotic Peening

Robotic Peening Breakthroughs That Are Transforming Surface Treatment Today

Introduction

Robotic peening is shaking up the surface treatment game—and I’m here for it. Gone are the days of guesswork, operator fatigue, and inconsistent coverage. We’re entering an era where robots don’t just replace hands; they perfect the art. And honestly? That’s exciting. Imagine something as rugged as shot peening getting a sleek robotic makeover that delivers surgical precision. You see, when machines learn to master the science of stress manipulation, durability becomes an engineered guarantee, not a hopeful outcome. Let’s dig into why robotic peening isn’t just a trend—it’s the standard every high‑performance industry didn’t know it was waiting for.

Understanding the basics of robotic peening and how it differs from traditional methods

Robotic peening redefines the traditional shot peening approach by integrating programmable robots in place of manual or semi‑automated machines. In conventional methods, an operator controls the nozzle or wheel to bombard a component with abrasive media—relying on experience and repetitive motion. With robotic peening, the robot arm’s path, speed, angle, and peening intensity are pre‑programmed, ensuring uniform coverage and repeatable performance.

This marks a huge leap. Traditional peening often suffers from human‑induced variability—different operators, fatigue, even a small misalignment can throw off the optimal coverage. Robotic systems eliminate those variables. They follow precise toolpaths with millimeter accuracy, apply the same force consistently, and avoid sloppy coverage zones that lead to under‑ or over‑peening.

Another difference lies in control and documentation. Many robotic peening systems integrate process monitoring sensors and closed‑loop feedback. That means real‑time tracking of variables like air pressure, peening intensity, and coverage rate—logging them for quality assurance. Traditional systems often lack such traceability, making certification harder in regulated industries.

The rise of automation in surface finishing and why robotic peening is leading the way

Automation is sweeping across surface finishing—from deburring and polishing to coating. But peening is unique: it actively alters material properties, not just appearance. That’s why robotic peening is at the forefront. Industries like aerospace and automotive demand high‑reliability components with verified fatigue resistance. Robotic systems address that demand by reducing variability and cementing process traceability.

Industry 4.0 has set a new bar. Manufacturers want interconnected systems that feed data into MES (Manufacturing Execution Systems) and perform predictive maintenance. Robotic peening aligns perfectly—it can record data, trigger alerts if parameters drift, and integrate into fully automated production lines. That’s a major draw for OEMs looking to digitize operations.

Also, workforce dynamics play a role. Skilled labor is in short supply, and repetitive tasks like standing over a blast cabinet are no longer acceptable long‑term roles. Automation frees up personnel to focus on higher‑value tasks like inspection, analysis, and process improvement. Robotic peening not only meets quality demands—it improves job satisfaction and safety.

Core components and working principles of a robotic peening system

A typical robotic peening cell includes several key parts: the industrial robot arm, the peening gun (typically air‑blasted or wheel‑type), media delivery and recovery systems, safety enclosures, and control software. The robot arm positions the gun at programmed angles and velocities. The media system handles abrasive shot or beads, replenishing the supply and recycling spent media.

Under the hood, the software defines toolpaths based on the component’s CAD model. Parameters like standoff distance, peening intensity (Almen intensity or arc height), coverage percentage, and pass count can all be tuned. The robot executes moves with high fidelity—this level of control is impossible with manual methods.

Closed‑loop monitoring is critical. Sensors track peening intensity (via devices like in‑line Almen sensors), air pressure, and flow rate. If variations occur, the system automatically adjusts or flags the run. This self‑governing feedback ensures every part meets specs, critical in aerospace or safety‑critical industries.

Benefits of robotic peening in aerospace, automotive, and heavy machinery industries

Aerospace components like landing gear struts, turbine blades, and fasteners gain immense benefit from consistent fatigue strength. Robotic peening ensures every critical feature gets the same depth and coverage—eliminating weak links. Reduced scrap rates, fewer fatigue failures in service, and better lifecycle data all follow.

In automotive, shot‑peened parts like crankshafts, gears, and suspension components see longer lives and higher performance under stress. Robotic peening boosts repeatability, enabling OEMs to claim tighter warranties and lower maintenance costs. Especially for EV drivetrains, where weight and stress margins are tighter than ever, every psi of compressive surface stress counts.

Heavy machinery and oil & gas equipment get similar benefits. Hydraulic cylinders, shafts, and tubular steel suffer from cyclic loading and environmental exposure. Robotic peening can be applied even in retrofit cells, boosting structural integrity and preventing premature failure in field components. This translates to lower downtime and replacement expenses.

How robotic peening enhances fatigue resistance and component longevity

Fatigue starts at the surface—tiny cracks grow under cyclic loading. Shot peening embeds compressive residual stress that opposes crack initiation. Robotic peening ensures the required stress depth (often 0.3 mm or more) and uniformity across every edge, bore, and face. That consistency increases lifespan by up to 300% in some test cases.

Let’s get specific: test samples peened robotically vs manually often show a higher Almen arc height—indicating deeper residual stress—and nearly identical coverage across repeated runs. That means a part isn’t only stronger—it won’t surprise you by popping when you least expect it.

Moreover, inconsistencies in manual peening can create hotspots of tensile stress—opposite to what we want. Robotic peening eliminates these anomalies. When every pass is identical, you avoid fatigue cracks caused by process errors. That’s reliability—which industries can quantify in MTBF (Mean Time Between Failure) figures.

Case studies and real-world data proving robotic peening performance

In one aerospace OEM study, robotic peened landing‑gear bolts outperformed manually peened samples in full fatigue testing—enduring 1.8 × longer before crack initiation. That meant fewer replacements, less downtime, and a bump in airworthiness margins.

An automotive supplier replaced manual peening on transmission gears with robotic cells. They reduced scrap by 45%, improved consistency by ±5%, and increased line throughput 25%—all while reducing labor hours by 30%.

A heavy‑industry retrofit project integrated a robotic cell to peen large hydraulic pistons. The result? A 2× increase in fatigue life and a 20% reduction in on‑site rework. Operators reported a safer, cleaner work area—and management logged solid ROI in under 18 months.

Challenges and limitations of implementing robotic peening in industrial settings

Robotic peening isn’t plug‑and‑play. Programming toolpaths and tuning parameters requires expertise—both robotics and materials science know‑how are needed. That steepens the learning curve compared to manual peening.

Space and infrastructure can be hurdles. These cells need enclosures, ventilation, media-reclamation systems, and safety interlocks. Smaller shops may struggle to carve out a peening bay, and retrofits can require concrete pads and compressed‑air upgrades.

Finally, ROI analysis must account for upfront costs. Robot stations can range from US $150K to $500K+ depending on arm complexity, cell size, automation level, and monitoring systems. For small‑batch shops, the cost must be justified by improved yield, quality, or throughput.

Key considerations for selecting a robotic peening solution for your application

First, define peening intensity requirements. Do you need moderate coverage or high‑intensity peening with deep compressive stress (~.010–.020″ arc heights)? That determines the air volume, nozzle selection, and housing.

Next, size and geometry matter. Large shafts vs small precision parts will affect robot arm reach, payload capacity, and cell design. Partnering with integrators who can prototype the robot toolpath on sample parts is crucial.

Don’t forget monitoring features. Systems with real‑time intensity measurement and coverage verification help your audit trail and certification if you’re in regulated industries. Software integration—like link to MES or Industry 4.0 dashboards—is also a big plus.

Emerging trends: AI integration, adaptive algorithms, and real-time feedback in robotic peening

Nowadays, peening robots are getting smarter. AI‑driven adaptive peening systems analyze sensor data mid‑cycle and adjust parameters to hit the perfect intensity. That means even worn nozzles or changing media size won’t compromise the process.

Machine‑learning can predict when abrasive media needs replenishment or when tool wear is nearing thresholds. Maintenance becomes predictive—not just scheduled. That improves uptime and prevents surprise failures.

Real‑time vision systems, too, can inspect coverage in situ. Combined with sensor data, robots can validate complete coverage before toolpath ends—triggering an automatic new pass or flagging parts if they don’t meet criteria.

Future outlook: How robotic peening is shaping the next generation of manufacturing

Robotic peening is poised to expand beyond heavy machinery into more niche applications—medical implants, 3D‑printed aerospace parts, even consumer electronics shells with stress‑relief requirements. As cell costs drop and competence spreads, adoption will grow.

Integration with digital twins means peening parameters will be simulated before real‑world runs. That minimizes trial time and ensures first‑pass success. The robot becomes part of a fully digital production ecosystem.

Eventually, every manufacturing line handling metal components may include a peening station—automated, integrated, monitored. Surface stress control isn’t a niche add‑on anymore—it’s a standard quality requirement. Robotic peening is leading that transformation.

Conclusion

Robotic peening isn’t just the next phase in surface treatment—it’s the precision revolution manufacturers didn’t realize they needed until now. We’ve unpacked how this technology outperforms traditional methods, boosts fatigue life, drives consistency, and plugs seamlessly into automated production lines. From aerospace to automotive and beyond, the data is clear: robotic peening delivers smarter, safer, and stronger outcomes.

As industries chase tighter tolerances and longer-lasting parts, the question isn’t if robotic peening fits into your workflow—it’s when. So, whether you’re a plant manager looking to boost efficiency or a curious engineer chasing that extra edge in durability, now’s the time to start the conversation.

Got thoughts on where robotic peening is heading? Leave a comment below or share this post with someone who’s ready to automate smarter.